Support your aging and diverse workforce.

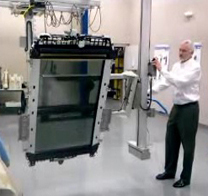

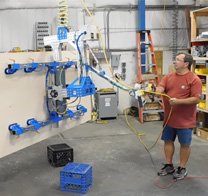

We design ergonomic lifts and work station systems that will improve your safety record and increase productivity.

Cynergy Ergonomics provides lift assist machines that allow operators to easily and effortlessly handle heavy, large products such as machinings, weldments, panels, rolls, electronics, ceramics, bags, etc.

Ergonomic material handling equipment and work stations are cost effective and profitable alternatives to worker injuries and product damage. Our systems are utilized when weights, repetitive movements, working posture or nature of the movement creates injury hazards for the individuals performing these tasks. Along with safety concerns, risk management issues are addressed when ergonomic lifts and work stations are applied to the job environment (reduced workers compensation cost, lower EMR ratings, etc.).

Click our PRODUCTS tab to review the various solutions we offer; click our VIDEO tab to see these machines in action.

Custom Lifting Devices

Custom Lifting Devices Gorbel G Force

Gorbel G Force Manipulator Arm

Manipulator Arm Mobile Lifters

Mobile Lifters Roll Handling Equipment

Roll Handling Equipment Ergonomic Workstations

Ergonomic Workstations Vacuum Lifting Equipment

Vacuum Lifting Equipment Vacuum Tube Lifter

Vacuum Tube Lifter

Follow Us!